We provide customized PLC Training on PLCs like Allen Bradley, Siemens, Schneider, Mitsubishi, Delta, Omron & ABB.

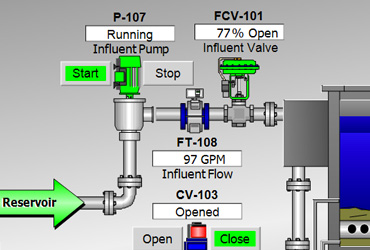

SCADA is real time platform where operator can see the current scenario of the plant, can take action for betterment of process or can analyse best environment for the process based on the historical data.

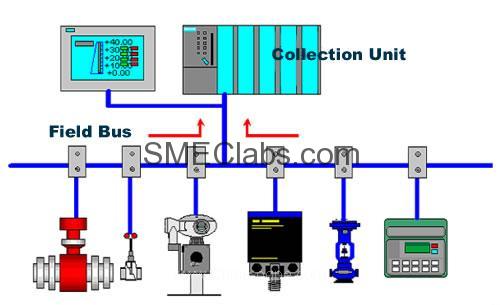

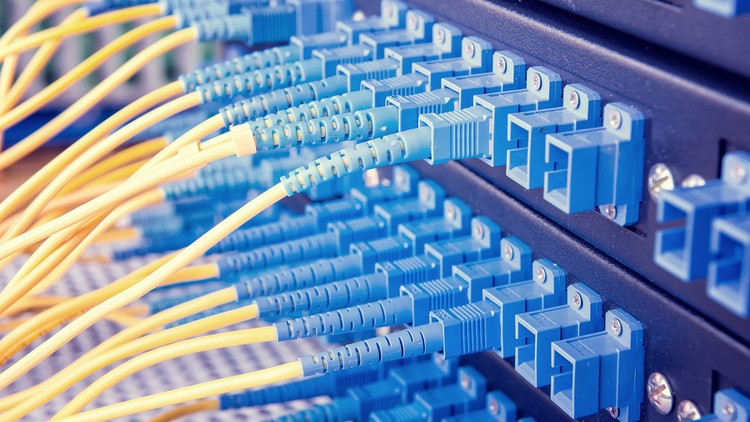

This course covers the standard networking devices and protocols in industry. Networking of PLCs is commonly used in Industries for controlling multiple processes. Participants get maximum practical exposure to networking devices and configuration of custom networks.